Punjab Sugar Industry

Punjab Sugar Industry is currently going through difficult times just like the sugar industries of several other states in India. Financial and infrastructural problems are believed to be the main reasons behind the problems plaguing Punjab’s sugar industry.

The cost of production of sugar is very high in Punjab, which is the main cause of the financial crunch. Because of this, the units engaged in sugar production are making huge losses. The Punjab sugar industry is facing tremendous odds and it has become extremely difficult to continue running the industry. The cost of sugar production is way beyond the present market price of the sugar, so it is not viable pertaining to the economic condition to continue with the production of sugar. The situation is very delicate and at the same time very strange because the farmers are demanding a price hike for their sugarcane whereas the mills are not able to pay the present rate at which sugar is sold.

The situation is going to improve with the new methods of production. In order to make the sugar industry have sustainable growth, it is important to have an easy access to adequate amounts of basic ingredients at a competitive price structure in order to compete along with the other low cost sugar manufacturing countries such as Australia, Thailand, and Brazil. The cost of the sugarcane has to be economical to lower the production cost of sugar.

Mechanized Pit Planning is a new kind of agricultural method which uses the latest techniques to boost the yield or the harvest by the means of organic techniques of agriculture.

The initial expenses in case of mechanized pit method is ` 15,500 whereas in case of traditional method it is ` 11,782

The harvesting and transportation in case of mechanized pit method is ` 10,000 whereas in case of traditional method it is ` 5,000

The total expenses in case of mechanized pit method is ` 25,500 whereas in case of traditional method it is ` 19,782 The total income in case of mechanized pit method is ` 47,400 whereas in case of traditional method it is ` 25,000. The net profits in case of mechanized pit method is ` 21,900 whereas in case of traditional method it is ` 8,218.

Pest Control |

Balrampur Chini Mills

The cost of production of sugar is very high in Punjab, which is the main cause of the financial crunch. Because of this, the units engaged in sugar production are making huge losses. The Punjab sugar industry is facing tremendous odds and it has become extremely difficult to continue running the industry. The cost of sugar production is way beyond the present market price of the sugar, so it is not viable pertaining to the economic condition to continue with the production of sugar. The situation is very delicate and at the same time very strange because the farmers are demanding a price hike for their sugarcane whereas the mills are not able to pay the present rate at which sugar is sold.

The situation is going to improve with the new methods of production. In order to make the sugar industry have sustainable growth, it is important to have an easy access to adequate amounts of basic ingredients at a competitive price structure in order to compete along with the other low cost sugar manufacturing countries such as Australia, Thailand, and Brazil. The cost of the sugarcane has to be economical to lower the production cost of sugar.

Mechanized Pit Planning is a new kind of agricultural method which uses the latest techniques to boost the yield or the harvest by the means of organic techniques of agriculture.

Important aspects of mechanized pit method in Punjab Sugar Industry:

- Improvements in the planting techniques, manipulation of soil, etc.

- The use of organic fertilizers to make the soil fertile and not harming the environment. Preparation of compost is the primary in organic farming. This helps the plant to grow to its potential. Other naturally occurring substances like limestone powder, dolomite powder, bone meal, dried seaweeds can be used to increase the fertility of the soil.

- The provision of better irrigation facilities.

- The use of certain beneficial insects like wasps, ladybirds, and bees for the controlling the growth of the insects that harm the crops. This would allow the farmers to control the pests with out harming the ecological balance.

- The use of age old weeding processes like hoeing and hand weeding, using small herbivorous animals to eat the weeds and its seeds, flame weeding, in place of poisonous inorganic herbicides or special bio engineered plants which are immune to the herbicides.

- To depend on natural methods to tackle problems like pest control, soil fertility, diseases of the plants, weed control, extreme climate, etc.

- The use of organic pesticides such as certain germs that affect the life cycle of the pests, pheromone traps, etc. These pesticides are different pertaining to different plants.

- To provide sufficient amount of moisture, light, air.

- The open area of farming makes the operation easier than the present methods.

Comparative analysis of Mechanized Pit Planning and present method:

For more information contact :

[email protected]

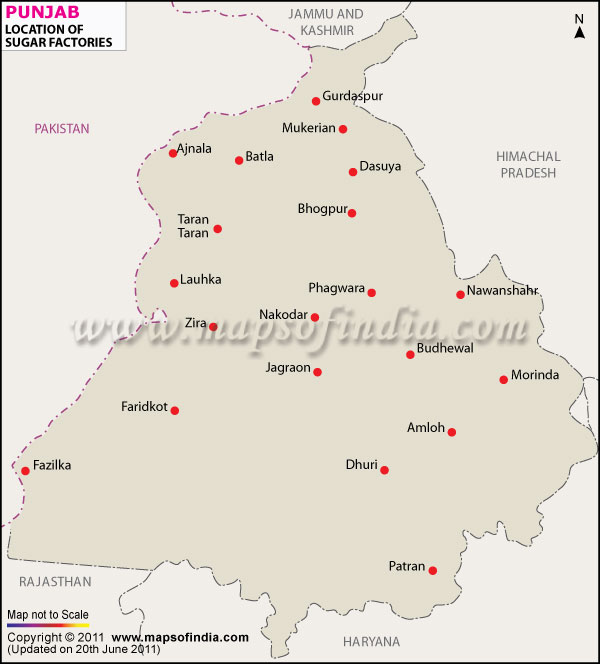

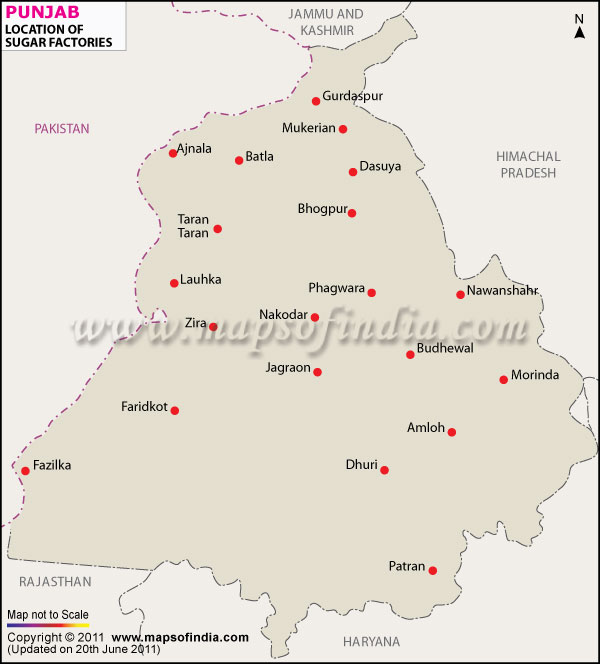

Disclaimer : All efforts have been made to make this image accurate. However Compare Infobase Limited and its directors do not own any responsibility for the correctness or authenticity of the same.

Disclaimer : All efforts have been made to make this image accurate. However Compare Infobase Limited and its directors do not own any responsibility for the correctness or authenticity of the same.

Sugar Industry in Punjab

| Sugar Factories | Details |

| Rana Sugars Ltd. Buttar Savian, Baba Bakala, Amritsar (Punjab) |

From 2500 to 5000 TCD |

| The Budhewal Co-op. Sugar Mills Ltd. Budhewal, Ludhiana (Punjab) |

From 1250 to 2500 TCD |

| The Doaba Co-op. Sugar Mills Ltd. Banga Road, Nawanshahr, Jalandhar, Punjab |

From 2500 to 5000 TCD |

| The Nakodar Co-op. Sugar Mills Ltd Mehatpur Rd, Nakodar, Jalandhar, Punjab |

From 1250 to 2500 TCD |

| The Patiala Co-op. Sugar Mill Ltd Patiala Nabha Road, Patiala, Punjab |

From 1250 to 2500 TCD |

| The Punjab Agro Industries Corpn. Ltd Around Lopoke, Dist. Amritsar |

Date 9-10-90, P.S. Crushing Capacity 2500 |

| The Punjab State Fedn. of Coop.Sugar Mills Ltd At Teh.Dasuya, Dist. Hoshiarpur, Punjab |

Date 26-10-90, Coop. Crushing Capacity 2500 |

Related Links